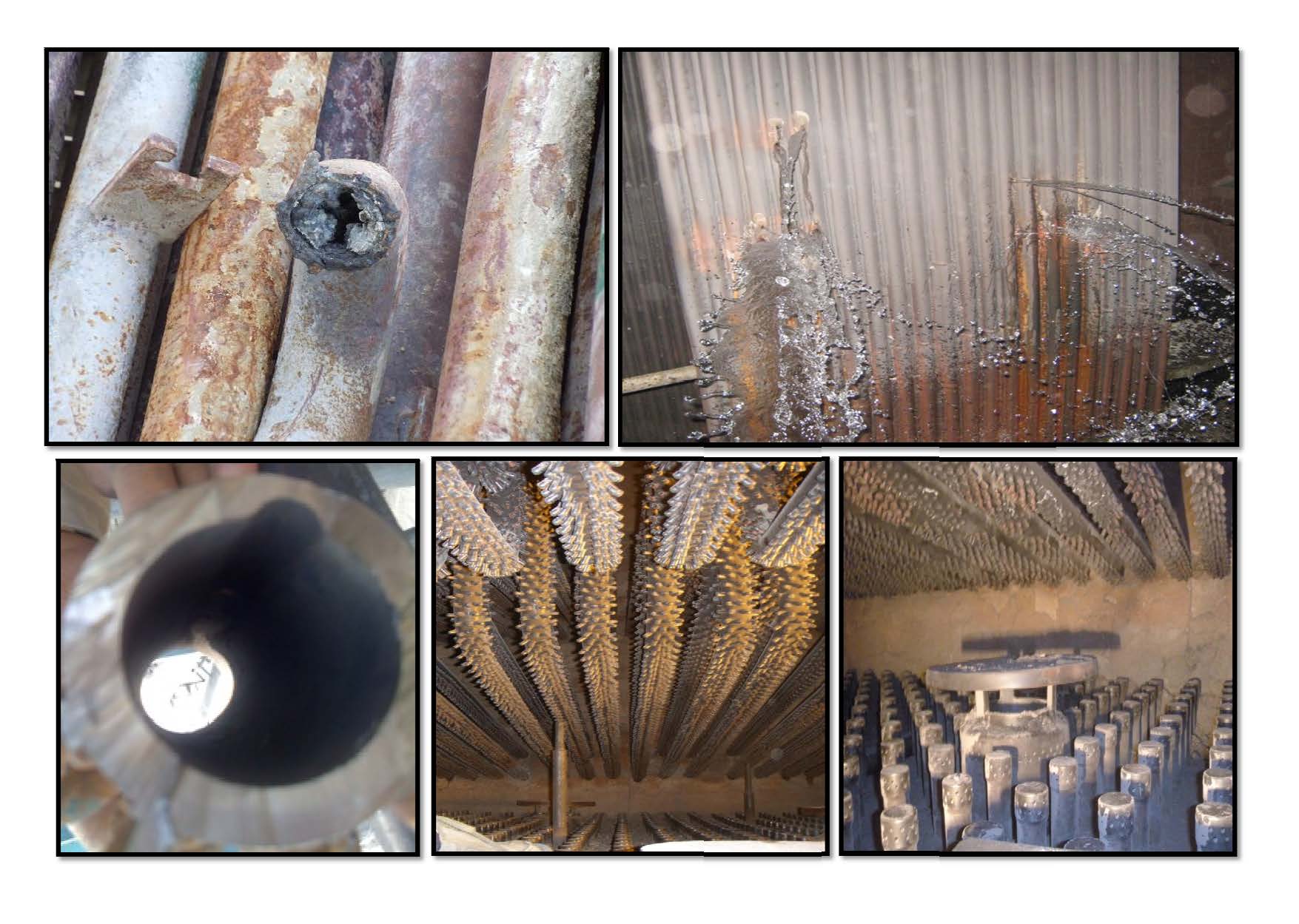

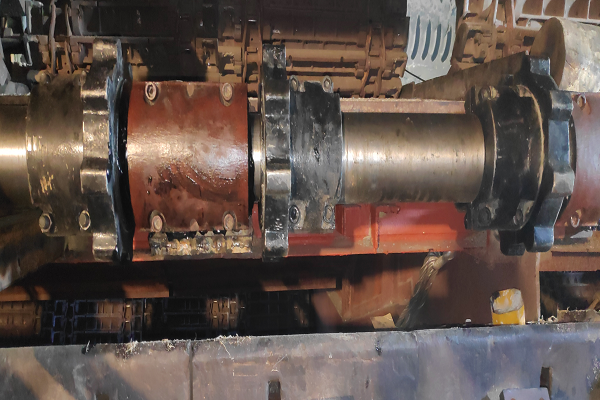

In continuation of our earlier post & video which was posted in May 2023 regarding heavy puffing oscillation & vibration in Buckstay and Front water wall of boiler......

In continuation of our earlier post & video which was posted in May 2023 regarding heavy puffing oscillation & vibration in Buckstay and Front water wall of boiler......

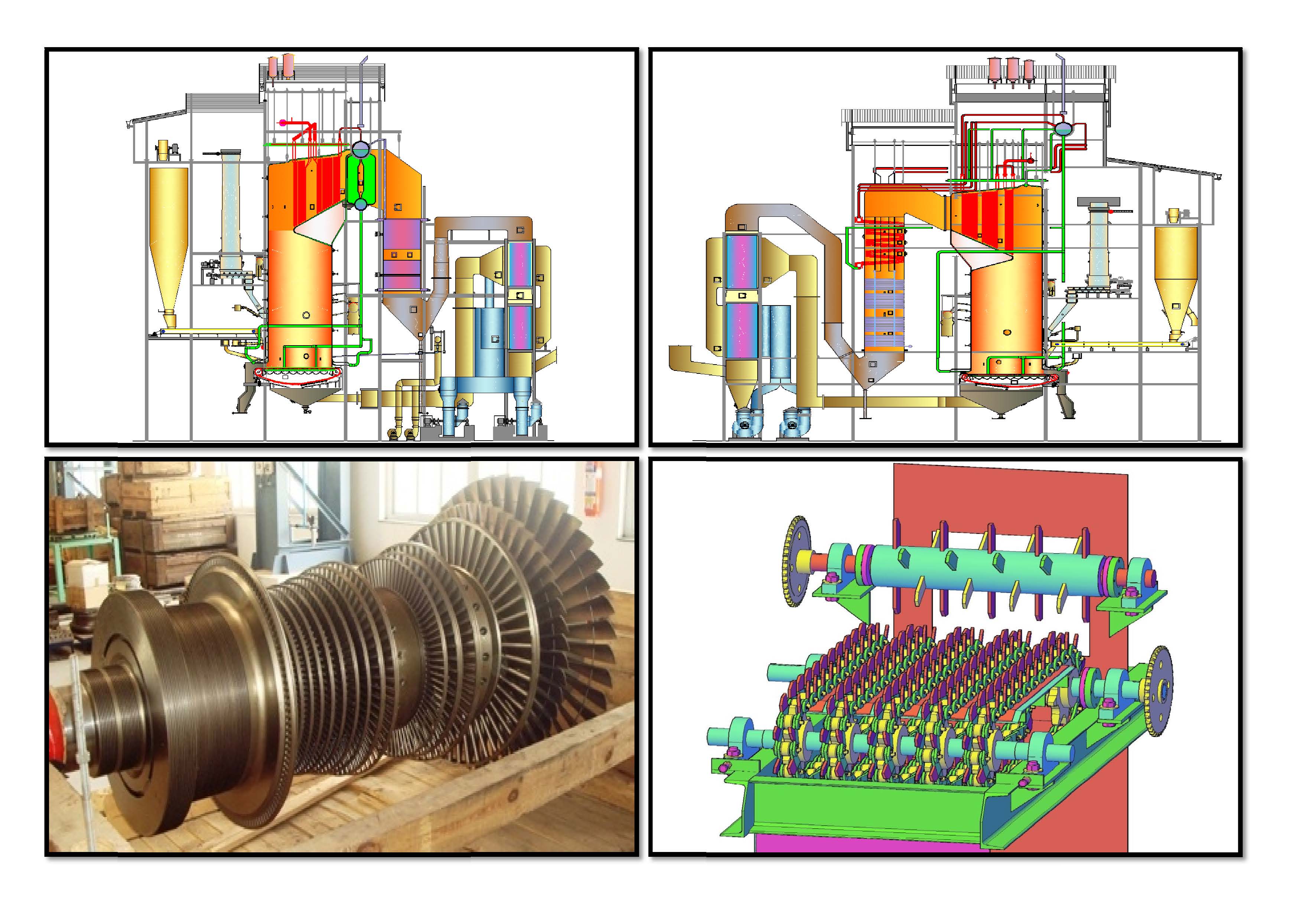

When steam demand increases, Most of the companies think about capacity enhancement of existing Boilers OR Fuel conversion. OEM & Experts suggested a lot of proposals with high cost involvement for Boiler modification for only 10 to 15 % increment in boiler steam capacity against the rated boiler capacity.....

Selection of Boiler’s steam drum level set points for alarm and safe level trip interlock limit for failsafe operation of boiler to avoid pressure parts failure is primary responsibility of OEM & Design team for designing of adequate steam drum sizing at the time of low drum level & low-low drum level operation in boiler....

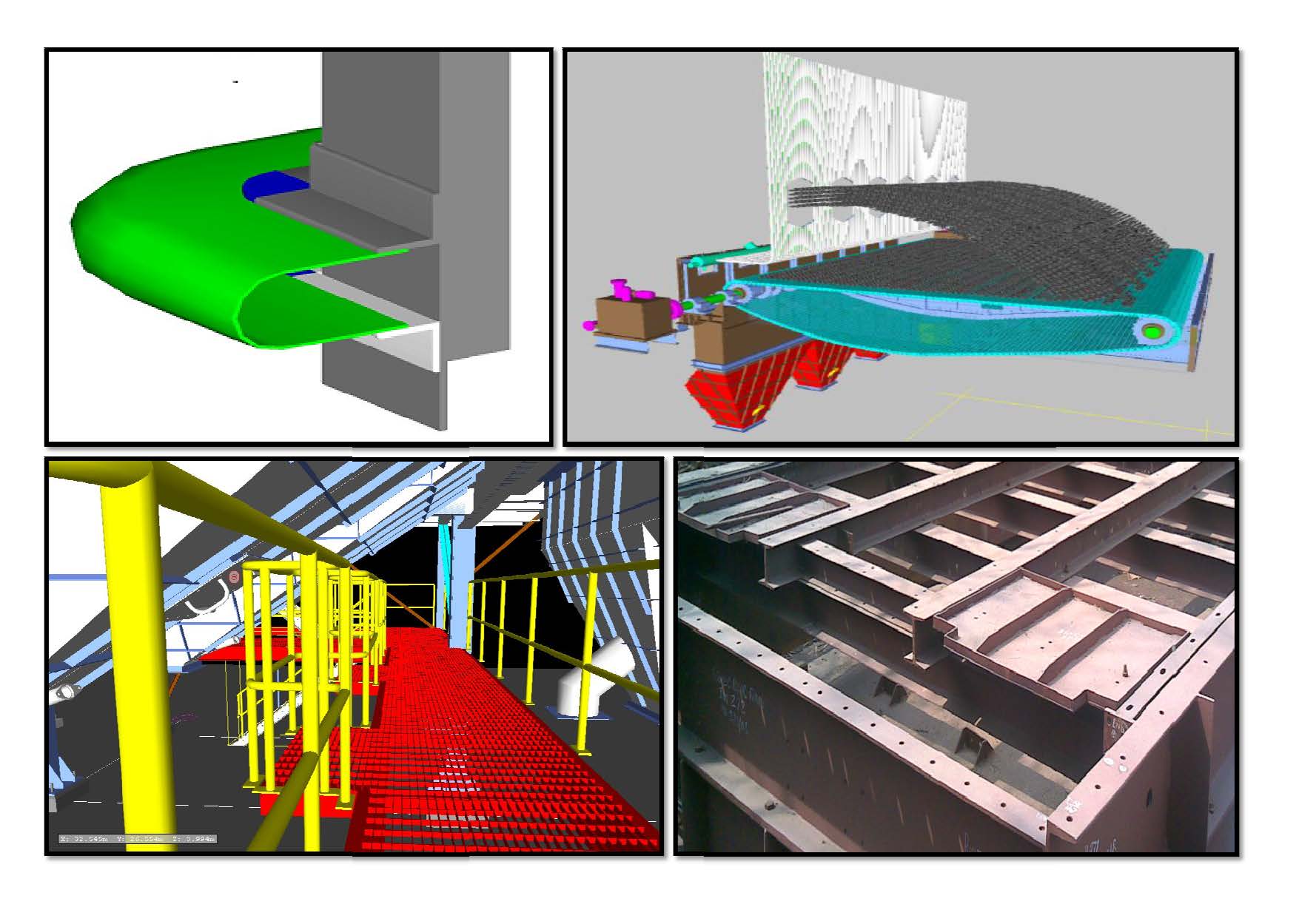

Fuel combustion in boiler i.e. Triple-T = TIME, TEMPERATURE & TURBULENCE. Normally major boiler efficiency game changer values during design calculations are predicted parameters like Unburnt Carbon Losses, Flue Gas Temperature at APH outlet, Excess Air requirement....

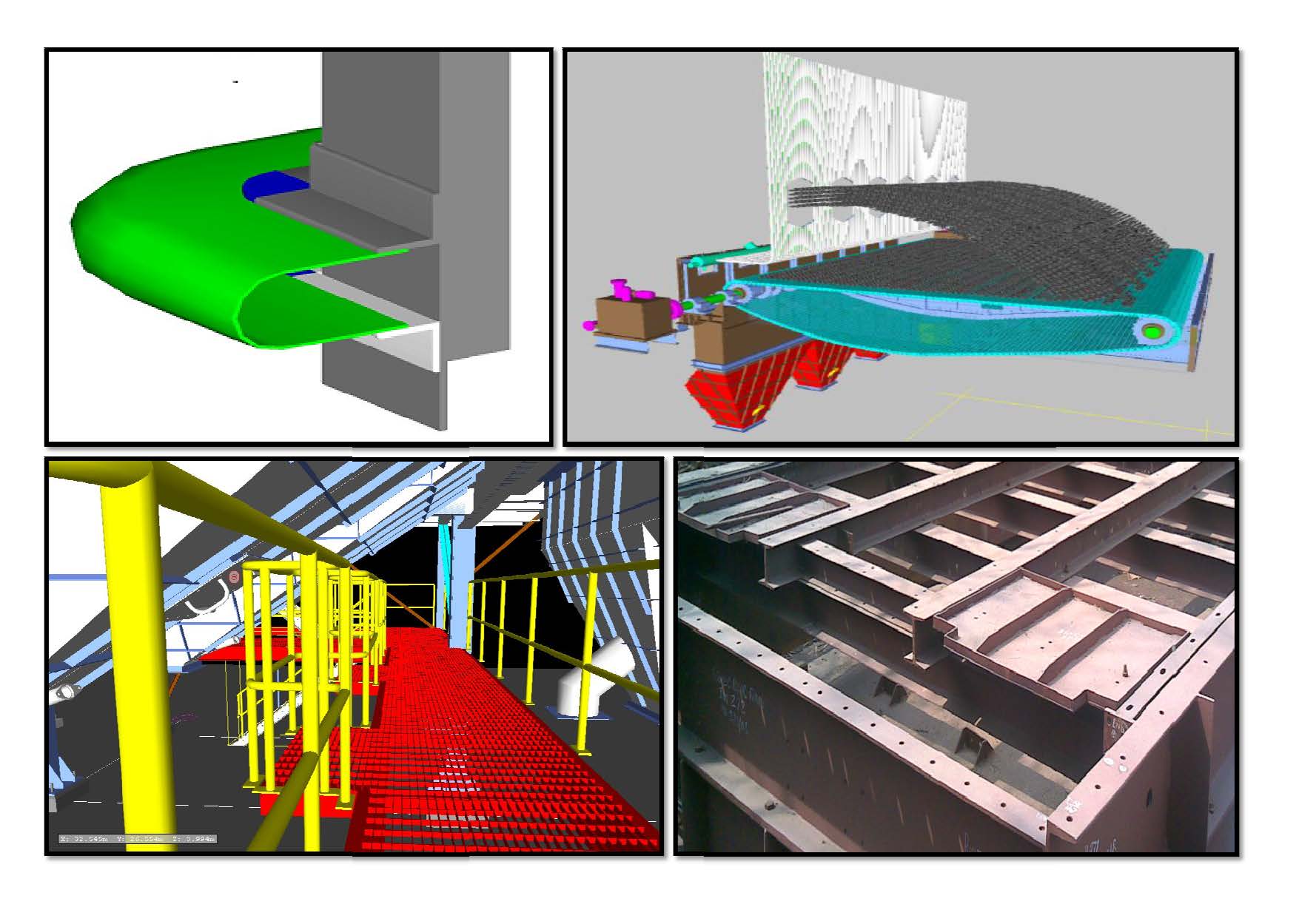

Any Boiler design starts with the calculation of circulation ratio based on the drum working / operating pressure. The circulation ratio is immensely important for providing safe cooling of the heated tubes. Any adjustment & efforts for cost cutting & value engineering will leave a huge impact on boiler maximum operating life....

Trouble starts with the start of a New Boiler and complete elimination is like a daydream. We need to accommodate and survive with best operational & efficiency parameters and minimum failure and downtime

Buckstay play a major role in water wall panel strengthening and control guiding of expansion movement of pressure parts in boiler. Any deficiency in buckstay design, erection & routine maintenance leave a huge impact on boiler life and cost.

Boiler is given guarantee of engineering/design for life span of around 25 years but trouble starts within a short time period due to engineering issues comes on surface